Home > News > Application of Precision Hard and Brittle Material Laser Cutting Machine in Ceramic Processing

News

Application of Precision Hard and Brittle Material Laser Cutting Machine in Ceramic Processing

Ceramic materials are widely used in electronics, medical, aerospace and other fields due to their high hardness, high temperature resistance and corrosion resistance. However, their high brittleness and easy cracking make traditional processing face huge challenges. Precision hard and brittle material laser cutting machine provides innovative solutions for high-precision and low-damage cutting of ceramics through non-contact processing and ultrafast laser technology, promoting the upgrading of high-end manufacturing.

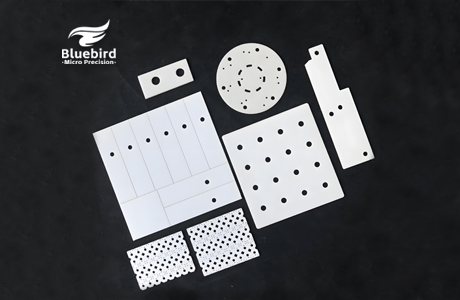

Traditional mechanical processing is prone to produce microcracks or edge collapse on the surface of ceramics, and the yield rate is less than 50%. Femtosecond/picosecond lasers achieve "cold processing" through ultrashort pulses (10^-12~10^-15 seconds), with a heat-affected zone of less than 10μm, a smooth incision without burrs, and an edge collapse size controlled within 5μm, which is especially suitable for cutting precision ceramic substrates such as alumina and silicon nitride. For example, in the field of electronic packaging, laser technology can achieve ±2μm precision microhole array processing on a 0.2mm thick ceramic substrate to ensure the stability of high-frequency signal transmission.

Laser cutting machines break through the limitations of traditional processes on ceramic structures and support flexible processing of microchannels and hollow patterns. For example, artificial joints and dental implants in the medical field need to process porous structures on zirconia ceramics to promote bone integration. Laser technology achieves uniform distribution of pore sizes of 50~200μm through dynamic focusing and path optimization, and the processing efficiency is more than 3 times higher than that of traditional etching processes.

From high-purity alumina to silicon carbide composites, laser cutting adapts to different ceramic materials through intelligent adjustment of wavelength and energy parameters. For example, ultraviolet lasers are suitable for non-destructive cutting of transparent ceramics (such as sapphire), while fiber lasers can efficiently process black silicon nitride ceramics. The non-contact process reduces dust pollution and coolant use, and increases material utilization by more than 20%, which is in line with the trend of green manufacturing.